Autodesk is a Enterprise Reporter shopper

Autodesk’s Jeff Kinder on why digital transformation is a win-win for shoppers and companies

Over the previous few a long time, society has lived by ongoing levels of technological transformation. Music went from data to cassette tapes to CDs and now streaming platforms akin to Spotify. Tv was born with black-and-white TV units and antennas, evolving by cable and satellite tv for pc tv to as we speak’s on-demand, wherever, anytime streaming companies. Simply 15 years in the past, banking at house through an app was in its infancy. Now, that’s the norm.

This thread of streamlining each day processes has naturally discovered its approach into the office. Communication instruments akin to electronic mail and Slack have revolutionised how we talk at work. Cloud-based companies akin to Dropbox and Google Drive allow groups to retailer giant portions of knowledge and share recordsdata simply. Some design and manufacturing companies are utilizing AI-powered instruments akin to generative design to create design choices sooner than ever earlier than – and there’s nonetheless room for progress.

Jeff Kinder, government vice chairman of Product Improvement and Manufacturing Options at Autodesk, has performed a key function in supporting numerous industries as they underwent digital transformation – from journey to banking and now design and manufacturing. Right here, he shares his insights on the instruments powering design and manufacturing’s present digital transformation.

Generally, what results does digital transformation have on companies and shoppers?

Digital transformation places new instruments, and a brand new stage of effectivity, in peoples’ arms, opening up their alternative to streamline processes and innovate. This finally advantages shoppers by price financial savings, improved product high quality and enhanced buyer experiences.

Constructing on that, how is the digital transformation in design and manufacturing impacting the business?

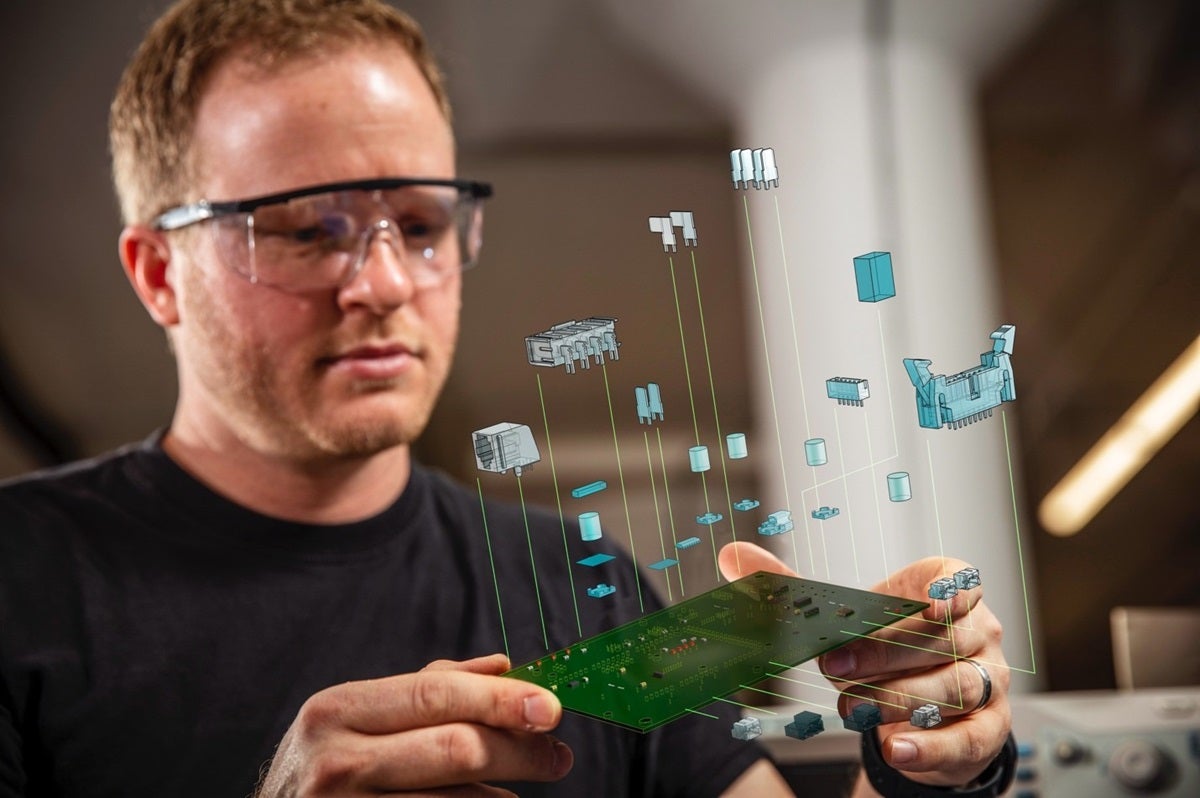

Leaders within the design and manufacturing business are presently targeted on creating the final word linked manufacturing facility. This imaginative and prescient encompasses seamless communication and collaboration between individuals and machines, pushed by entry to real-time information and superior analytics. The advantages companies on this house can count on to reap from present process transformation embrace enhanced effectivity, waste discount and a productiveness enhance.

As firms undertake extra environment friendly manufacturing processes, they’ll considerably decrease manufacturing prices. These financial savings typically translate to lowered costs for shoppers, making merchandise extra reasonably priced with out compromising high quality. Improved effectivity and innovation in manufacturing may yield higher-quality merchandise and sooner time to market. This ensures that customers have entry to the newest and finest choices extra shortly, and the producers bringing these merchandise to market have a leap on their rivals. Plus, it means many extra choices to select from in the marketplace.

What are some frequent challenges manufacturing companies face as we speak that digital transformation would assist remedy?

Many firms nonetheless use paper and whiteboards to trace their manufacturing processes and design adjustments. They’re absolutely conscious that it’s inefficient, they usually wish to collaborate sooner with colleagues and suppliers who’re at a distance from the store flooring. Nonetheless, their information administration system is usually native and never within the cloud, which holds them again. Paper travellers – literal envelopes of paper checklists and job directions – are nonetheless far more frequent than you’d count on. Autodesk’s function is to fulfill design and manufacturing companies the place they’re and assist them take subsequent steps towards utilizing the digital instruments accessible as we speak that assist them make higher selections sooner.

What instruments are powering design and manufacturing’s present digital transformation?

To some it could sound cliched, however in quite a few regards, the cloud is completely remodeling the manufacturing business. Anybody wherever can work on the identical undertaking on the identical time – whether or not it’s a workforce of designers working remotely or speaking with a producer on one other continent.

The cloud is totally shifting how firms use information, method workflows and programs and spur new progress. It’s all about connecting individuals, processes and your complete manufacturing ecosystem. And there’s the tangible results of designing and making merchandise with decrease price and fewer waste.

Automation, which more and more goes hand-in-hand with the cloud, is one other massive development shaping this present wave of transformation. The design and manufacturing business has embraced automation for the reason that industrial revolution and the early meeting line. It’s actually a cornerstone all through the business’s historical past. The present wave of automation sweeping the business is all about leveraging robotics and AI-powered instruments.

For instance, as increasingly companies realise the advantages of attaining optimised designs sooner, we’re seeing a wave of adopting automated design instruments akin to generative design. Inside minutes, generative design allows you to prioritise issues akin to weight, supplies, energy and extra to analyse and arrive at preferrred design concepts, assuaging the ache – and price – of designing a number of iterations from scratch.

How is the business reacting to those shifts?

Transformation of any variety is tough. There’ll all the time be resistance at first. Nonetheless, if you do it proper – and with the precise companions supporting the method – the reward is huge for each companies and end-customers.

Some of the tough levels of getting companies on board with the cloud is altering the workforce’s mindset round information safety. After which really implementing new instruments and procedures brings its personal set of logistical challenges. There’s no debating both of these hurdles.

The design and manufacturing business has not grown up with ease-of-use as a trademark on the subject of its know-how instruments and information administration. At Autodesk, it’s our job to assist firms realise the advantages of shifting to the cloud within the context of their particular enterprise wants. For each giant and small clients, we give attention to guiding firms to a contemporary, environment friendly, productivity-increasing design-and-make expertise.

Is there any trepidation from companies?

This may sound stunning, however producers actually do like new and rising know-how as a result of it gives a bonus in an more and more aggressive business. Producers have lengthy embraced know-how adjustments to drive productiveness of their industries. As know-how change accelerates, producers can’t afford to fall behind, in order that they proceed to be taught new instruments and adapt.

As soon as they see the advantages of recent instruments and procedures, it turns into readily obvious why regularly staying on high of what’s across the subsequent nook, technologically, is essential. Nonetheless, additionally they can’t comply with each whim as a result of switching prices are actual. At Autodesk, we companion with our clients to assist them perceive what instruments and workflows are actually going to make a distinction to their companies.

What’s the most fun approach Autodesk is contributing to the manufacturing digital transformation?

Our perception is that if you wish to obtain breakthrough productiveness beneficial properties, it’s essential convey all design and manufacturing capabilities collectively right into a single, linked digital atmosphere, or “business cloud”.

Autodesk Fusion is our reply to this, and we’re seeing it change the “this device cuts, then this device drills, then this device polishes” point-to-point options of the previous. Prospects as soon as needed to develop a product design in a single device, then engineer it in one other, then program its manufacturing in one other. Now, they’ll do all of it with one device.

With Fusion, that step-by-step workflow and all of the associated information is linked. Individuals don’t should put a thumb drive in a machine, take it out and stick it into one other machine to switch essential undertaking information. Knowledge from the manufacturing course of, and even from the store flooring, can cycle again “upstream” to the design course of, to enhance the method of designing and manufacturing the subsequent product.

What sort of progress have you ever seen with design and manufacturing firms shifting to the cloud?

In as we speak’s business panorama, some firms are beginning to see that if you happen to’re not leveraging the cloud throughout product growth, you’re falling behind. Prospects are prepared to maneuver to the cloud as a result of the advantages are so tangible. Persons are coming to know the cloud is dependable and their information is protected. It’s been thrilling to see this shift as a result of it unlocks a lot potential for collaboration, reducing price, and connecting information. Now, as we proceed to introduce AI, having your information within the cloud makes it usable for AI fashions as properly.

Talking of AI, what can be its influence on design and manufacturing?

It’s fascinating to see the sudden curiosity and adoption of AI in comparison with the adoption of the cloud. The cloud was such a brand new idea and there weren’t too many shopper or industrial examples that folks might initially grasp onto. However now we casually stream music and films from the cloud, and get our maps and site visitors data from it immediately. It’s so engrained in our each day lives that we nearly take it without any consideration. AI, alternatively, appeared to have sprung from nowhere and now could be in every single place.

AI isn’t new to Autodesk, although. We pioneered the introduction of AI and machine studying for manufacturing with generative design greater than 10 years in the past, and we arrange an AI analysis workforce shortly after that. In order AI exploded, we had been properly positioned to launch Autodesk AI final yr at Autodesk College. That was simply its debut – count on to listen to extra about Autodesk AI within the months and years to come back as we evolve it to assist our clients get probably the most out of what AI can provide.

One current instance of how we’re already delivering on this initiative is the launch of drawing automation in Fusion. Creating 2D drawing variations of 3D fashions is a crucial step in product growth as a result of they primarily act as design blueprints for producers to interpret and work from throughout manufacturing. Nonetheless, we discovered that engineers spend as a lot as 40 per cent of their design time creating drawings.

Drawing automation eliminates the tedious steps concerned on this course of by robotically producing an correct 2D drawing. It helps engineers design sooner, be extra productive and talk extra successfully with producers.

As you talked about, digital transformations are always evolving. How ought to companies put together for the subsequent one?

As quickly as you consider a digital transformation is over, the clock is already ticking in your subsequent one. You must give it some thought as a steady course of. You all the time must intention for extra digital maturity, and a part of that maturity is embracing that there’ll all the time be change.

Autodesk’s purpose is for our clients to remain forward of the know-how curve at their very own tempo. We’ll proceed to give attention to serving to them undertake cloud know-how, perceive the advantages of digital transformation and uncover how information administration may help them collaborate higher. We’re going to make it straightforward and intuitive with the flexibility to understand worth shortly. That’s a should.

#driving #future #manufacturing #device #time

The Impartial

#driving #future #manufacturing #device #time

, 2024-12-18 11:28:00